Why You Need Stretch Wrapper Repair Service: Discovering Its Duty in Ensuring Product Packaging Quality and Safety And Security

Stretch wrappers play an essential duty in the product packaging procedure by guaranteeing the stability and honesty of bundled items. Nonetheless, they can encounter numerous issues that demand prompt repairs. Disregarding these repair services can cause considerable inefficiencies and possible item damage. Comprehending the ramifications of stretch wrapper maintenance is critical for any kind of service. This conversation will explore how routine fixings add to packaging high quality and safety, inevitably affecting the entire supply chain.

Understanding the Relevance of Stretch Wrappers in Product Packaging

Frequently neglected, stretch wrappers play a vital role in the product packaging process for various industries. These makers guarantee the safe packing of products, enhancing security and shielding products throughout transportation. By snugly covering items in stretch film, they lessen the danger of damage from shifting or ecological factors.In sectors like food, drugs, and manufacturing, effective packaging is important for preserving item stability and security (stretch wrapper repair). Stretch wrappers add to this by minimizing the probability of contamination and wasting, therefore prolonging rack life. Additionally, their performance advertises cost-effectiveness; businesses can enhance packaging procedures, minimizing labor costs and time.Moreover, stretch wrappers can fit various item sizes and shapes, making them versatile tools in packaging. Their capacity to adhere to different loads guarantees that even irregularly designed products are safeguarded correctly. To summarize, the importance of stretch wrappers can not be ignored in the quest for quality product packaging services

Typical Problems That Necessitate Stretch Wrapper Fixing

Stretch wrappers, while essential for preserving packaging honesty, can run into various functional concerns that demand repair. Typical problems include inconsistent tension, which might lead to broken or loose loads, jeopardizing product defense during transport. In addition, malfunctioning sensing units can interrupt the covering procedure, leading to irregular application of stretch movie. Worn-out rollers or belts may trigger slippage, preventing the wrapper's efficiency and causing delays in manufacturing. Concerns with the control system can lead to incorrect setups, influencing the total wrapping top quality. Dust and particles accumulation in mechanical parts can also bring about use and tear, requiring regular upkeep to stop break downs. Recognizing these problems beforehand is necessary, as prompt repair work can substantially prolong the life expectancy of the stretch wrapper and preserve suitable packaging criteria. Attending to these common problems guarantees that services can continue to operate smoothly and deliver items safely.

The Effect of Overlooking Repair Services on Product Packaging Performance

Enhancing Product Security With Routine Maintenance

Routine maintenance of stretch wrappers is crucial for avoiding packaging failings that can endanger product safety and security. By dealing with wear and tear without delay, business can greatly minimize product damage and assurance that equipment runs constantly. This positive technique not only safeguards the integrity of the items but additionally enhances general functional performance.

Avoiding Packaging Failures

Reliable upkeep of packaging equipment is crucial for protecting against failings that can compromise item security. Regular evaluations and prompt fixings of stretch wrappers aid determine potential concerns before they escalate right into substantial issues. When stretch wrappers are properly maintained, they operate at peak performance, making sure that items are securely wrapped and secured throughout storage space and transportation. Preventative maintenance timetables can substantially decrease the probability of mechanical failures, which typically cause packaging mistakes or breakdowns. By investing in routine checks, companies not only protect their products but additionally boost their overall operational effectiveness. This proactive method minimizes downtime and promotes a society of safety and security, eventually adding to greater customer contentment and rely on the brand name. Regular maintenance is consequently a cornerstone of reliable product packaging monitoring.

Minimizing Product Damage

Maintaining stretch wrappers is vital for reducing product damage and guaranteeing safety and security during handling and transportation. Normal upkeep of these makers helps identify and correct minor issues prior to they rise into substantial troubles, thus protecting the integrity of the covered items. When stretch wrappers run at peak efficiency, they give regular stress and protection, which decreases the risk of tons shifting throughout transit. stretch wrapper repair. This integrity avoids prospective damages that can occur from incorrect covering techniques, such as squashing or tearing of packaging products. Additionally, properly maintained stretch wrappers contribute to a safer workplace by minimizing the possibility of crashes triggered by unsteady or poorly wrapped loads. Eventually, thorough maintenance plays an essential function in guarding both items and employees throughout the supply chain

Making Certain Regular Efficiency

Regular efficiency of stretch wrappers is vital for improving item safety throughout the supply chain. Normal upkeep plays a crucial duty in making sure that stretch wrappers operate successfully, decreasing the possibility of tools failings that can endanger product packaging stability. By consistently evaluating and servicing these equipments, companies can recognize prospective issues before they intensify, therefore reducing downtime and protecting against product damage. In addition, well-maintained stretch wrappers apply consistent tension to packaging materials, guaranteeing that lots remain safe during transportation. This reliability not just secures items from dropping or moving but likewise fosters consumer count on the brand. Inevitably, prioritizing consistent efficiency via routine maintenance safeguards item top quality and enhances safety for both customers and manufacturers alike.

Cost-Benefit Analysis of Spending in Repair Solutions

Buying fixing services for stretch wrappers can result in substantial long-term savings by expanding devices life expectancy and minimizing the need for pricey replacements. In addition, prompt repairs aid stop tools downtime, ensuring regular manufacturing circulation. Enhanced packaging performance even more adds to general functional effectiveness, making repair work services a strategic factor to consider for organizations.

Long-Term Financial Savings Potential

Reviewing the long-term financial savings capacity of stretch wrapper repair work solutions discloses significant price benefits for services. By purchasing prompt fixings, companies can extend the lifespan of their devices, minimizing the regularity of pricey replacements. Furthermore, reliable stretch wrappers lessen product waste and warranty constant product quality, which subsequently enhances client fulfillment and minimizes returns.Moreover, a properly maintained stretch wrapper can cause reduced energy consumption and lowered operational prices. Repair services frequently feature service warranties that safeguard against future costs, supplying added monetary safety. On the whole, the aggressive technique of buying repair work solutions translates right into not only enhanced efficiency however additionally considerable savings gradually, making it a critical monetary decision for services aiming for sustainability and effectiveness.

Protecting Against Equipment Downtime

Prompt repairs to stretch wrappers can substantially decrease equipment downtime, a variable that directly browse this site affects functional effectiveness and productivity. When stretch wrappers breakdown, assembly line can halt, causing hold-ups in meeting orders and possible loss of revenue. Buying repair service solutions guarantees that devices stays in peak working problem, lessening the risk of unforeseen break downs. This positive method not only saves money over time but additionally improves labor force spirits, as workers can function without the disappointment of malfunctioning equipment. Additionally, keeping regular procedures enhances client complete satisfaction with dependable delivery times. Ultimately, the cost-benefit evaluation of purchasing fixing services highlights the relevance of avoiding downtime, as it fosters an extra efficient and secure workplace.

Improved Packaging Effectiveness

A significant enhancement in packaging efficiency can be attained via the efficient repair service of stretch wrappers. Properly maintained stretch wrappers enhance material use, decrease waste, and guarantee regular application of safety movie. stretch wrapper repair. By purchasing fixing services, companies can prolong the life of their devices, minimizing the need for costly substitutes. This positive method not only preserves performance yet additionally decreases labor expenses connected with manual re-wrapping or harmed pallets. Furthermore, enhanced devices efficiency can bring about faster packaging cycles, improving overall throughput. Inevitably, the cost-benefit evaluation reveals that purchasing stretch wrapper repair service solutions yields substantial returns by enhancing functional effectiveness, safeguarding item integrity, and ensuring that product packaging processes line up with market standards for top quality and safety and security

Picking the Right Company for Stretch Wrapper Repair Works

Just how can one assure that the selected service supplier for stretch wrapper repairs fulfills both top quality and efficiency requirements? Selecting the ideal provider needs cautious factor to consider of numerous aspects. First, assessing the supplier's experience and expertise in stretch wrapper repair services is important. A reputable company with a tried and tested record can supply assurance of their abilities. Furthermore, acquiring recommendations or testimonies from previous clients can provide insights into the company's reliability and service quality.Furthermore, evaluating the variety of services provided is required. A comprehensive repair work solution that consists of diagnostics, maintenance, and components replacement can facilitate much more reliable procedures. It's additionally advisable to ask concerning the provider's reaction time and availability for emergency situation repair services, as downtime can significantly affect performance. Lastly, examining cost-effectiveness without endangering high quality will assist in making an educated choice that straightens with functional needs and spending plan restrictions.

Best Practices for Keeping Your Stretch Wrapper Equipment

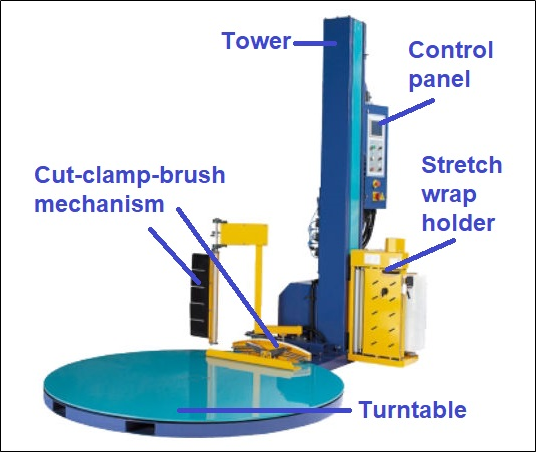

Keeping stretch wrapper equipment is important for ensuring peak efficiency and longevity. Regular examinations must be performed to determine any kind of signs of wear or damage, particularly in critical parts such as the movie carriage, rollers, and motors. Keeping the machine cost-free and clean from debris is crucial, as dirt can cause mechanical failings and inconsistent wrapping results. Lubricating relocating parts according to the supplier's standards will certainly boost performance and decrease friction. Additionally, operators ought to be educated to make use of the devices properly, as inappropriate usage can lead to early wear. navigate to these guys It is recommended to develop a regular upkeep routine, including checks for electric links and software application updates. Finally, maintaining an ample supply of substitute parts available can stop downtime during unanticipated fixings. By adhering to these ideal practices, companies can guarantee their stretch wrappers operate efficiently and add to total product packaging quality and security.

Frequently Asked Concerns

Just how Usually Should I Arrange Stretch Wrapper Maintenance?

Routine maintenance for stretch wrappers need to be scheduled every six months. However, increased use or specific operational needs might necessitate extra regular checks to guarantee peak efficiency and stop unexpected failures, enhancing total effectiveness.

Can I Repair a Stretch Wrapper Myself?

Fixing a stretch wrapper individually is possible, however it requires technical expertise and expertise. Blunders can cause further damage, so getting in touch with an expert or describing the manufacturer's guidelines is usually advised for effective repairs.

What Are the Indicators My Stretch Wrapper Requirements Fixing?

Indications that a stretch wrapper requires repair consist of irregular covering tension, noticeable damages to the film, unusual noises throughout operation, regular jams, and failing to appropriately secure loads. Timely interest is important to maintain efficiency and safety and security.

Just how Lengthy Does a Regular Stretch Wrapper Fixing Take?

The duration of a typical stretch wrapper repair work differs, typically taking between one to three hours, depending on the intricacy of the concern. Variables such as components accessibility and professional know-how likewise affect repair time.

Are There Guarantees for Stretch Wrapper Repair Work Services?

Guarantees for stretch wrapper repair solutions often differ by copyright. Usually, reliable companies offer limited guarantees covering components and labor, guaranteeing clients obtain trusted service and protection versus site link defects or concerns arising post-repair. Stretch wrappers, while vital for preserving packaging honesty, can run into various operational issues that demand repair work. Identifying these concerns early on is essential, as timely fixings can substantially extend the lifespan of the stretch wrapper and keep suitable product packaging criteria. Investing in repair solutions for stretch wrappers can lead to significant long-lasting financial savings by extending devices life expectancy and lowering the demand for expensive substitutes. In addition, efficient stretch wrappers reduce material waste and assurance consistent item quality, which in turn enhances customer contentment and decreases returns.Moreover, a well-kept stretch wrapper can lead to lower power consumption and reduced operational costs. A significant enhancement in product packaging efficiency can be accomplished with the effective repair service of stretch wrappers.